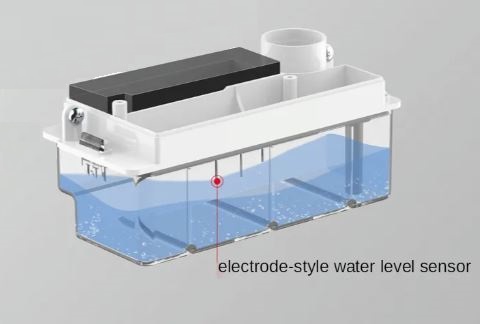

The Ultra Quiet Condensate Lift Removal System drainage pump has a flow rate of 24L/hr, a maximum lift of 12 meters, operates at an almost indiscernibly noise level of less than 19 decibels, and at only 3 Watts it is very energy efficient. The circuit board sealing treatment ensures that the pump is not affected by a humid environment, and the electrode type water level sensor solves the failure problems of traditional float water level sensors such as water absorption and jamming.

Condensate pumps are highly effective at resolving drainage line issues for poorly installed split-type AC systems and/or poorly installed drainage lines.

What constitutes a poorly installed drainage line? It’s really quite simple – any drainage line that must travel an excessively long distance horizontally will be prone to frequent blockages. And even worse – if a drainage line has any upwards inclination, or has any ‘valleys’ anywhere along its length, this will also lead to frequent blockages.

Drainage lines will always develop algae – no matter how well the drainage line is installed – as all of the ingredients for algae development exisit inside any condensate drainage line; moisture, humidity, bacteria, warmth, and an absence of UV light. So a poorly installed drainage line is any drainage line that has been installed is such a way that the development of algae is accelerated by areas where condensate pools and/or stagnates.

All air conditioning systems will produce condensation. Condensation is produced when the warm air being drawn in to the AC system passes over the evaporator coil which is cold. The condensation is directed into a drainage pan beneath the coil, and is then channeled into the drainage line. The condensate should be able to flow freely and rapidly until it connects to the main wastewater plumbing – ideally over the shortest distance as possible, and ideally through a drainage line that has a slight downwards inclination to faciliate rapid flow.

However, the reality is that most drainage lines for AC systems are installed horizontally – so the shorter the drainage line is, the better. Whilst some AC systems have their own built-in condensate pump (such as Cassette-Type ACs and various models of Fan-Coil Units), Split-Type AC systems are entirely reliant on gravity for condensate drainage.

The installation of a suitable condensate a pump can reduce or entirely eradicate drainage line blockages. This does not mean that one can forget about annual deep cleaning of ACs that have had a condensate pump installed – it is still recommended to deep clean any kind of AC system at least once per year, and this tpyically includes flushing out the drainage line.

Condensate pumps are available in all manner of specifications to ensure that they are ‘fit for purpose’ – as there are many variables that must be taken into consideration such as the BTU of the AC system, the volume of condensate produced, the drainage line issues that the pump is intended to assist with, where the pump is best installed to be most effective, the appropriate power supply for the pump, and the list goes on.

It is important (and often essential) that a site inspection is conducted to establish the root cause(s) of frequent drainage line blockages so that a suitable condensate pump can be selected for the requirements. Site inspections for the assessment of drainage line installation issues are charged at HKD 1,200 which is inclusive of the dismantling of 1 split-type AC system to assess for installation issues of the AC and it’s own drainage line, and an assessment of condensate flow from that particular unit. Each additional AC that requires dismantling for assessment (which is essential in cases where multiple ACs are connected to a shared drainage line) will be charged at HKD 400 each. After the conclusion of the site inspection, the AirCare Solutions technician will share videos (or photos where videos are not possible) of all issues and/or symptoms that have been identified, along with the conclusions that can be drawn from the issues and/or symptoms, and our Administration Personnel will follow up with recommendations for one or more possible solutions after they have received the site inspection report from the technician.

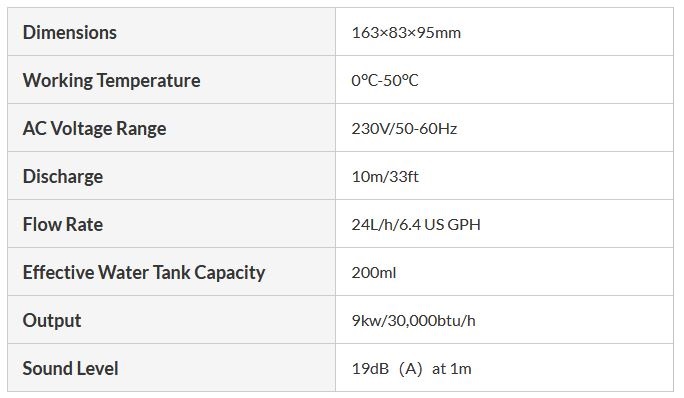

PRODUCT SPECIFICATIONS

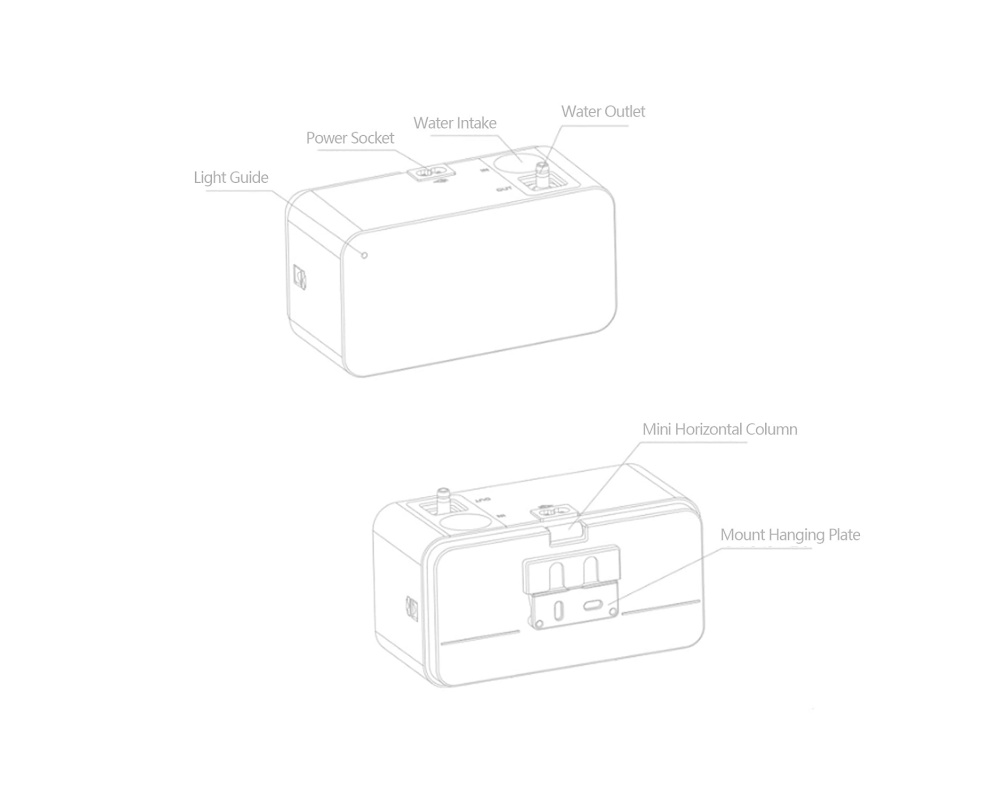

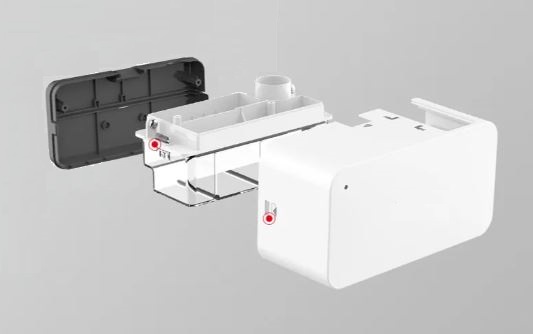

Quality of design ensures that the system is easy to dismantle for maintenance, and easy to reassemble

Electrode type water level sensor solves the failure problems of traditional float water level sensors such as water absorption and jamming

Pump is powered by a high quality DC motor